Introduction to the Environmental Impact of Sneakers

Have you ever stopped to think about what it takes to make your favorite pair of sneakers? Beneath the cool designs and cushioned soles lies a story of environmental consequences that’s rarely told. Sneakers, those everyday heroes of our wardrobes, aren’t just footwear—they’re also leaving footprints on our planet, and not in the way you’d hope. Let’s pull back the curtain and take a look at the hidden cost of these seemingly harmless kicks.

The Hidden Toll Behind Every Step

Your favorite sneakers might feel as light as air on your feet, but their journey from raw materials to retail shelves is anything but weightless. Did you know that the average pair of running shoes generates about 14 kilograms of CO₂? That’s roughly equivalent to keeping a lightbulb on for an entire week! Most of this impact comes from energy-intensive manufacturing processes and the use of synthetic materials that don’t exactly play nice with the Earth.

- Oil-derived plastics like EVA foam, used for those comfy midsoles, are non-biodegradable and take centuries to break down.

- Rubber soles: While durable, their production often involves deforestation and significant carbon emissions.

- Textiles: Polyester, a sneaker fave, relies heavily on petroleum and water-hungry dyeing processes.

It’s Not Just the Materials—It’s the Scale

Here’s the kicker (pun intended): Sneaker production isn’t a small-time operation. Global demand has skyrocketed, with over 24 billion pairs churned out annually. Imagine a mountain of sneakers large enough to block entire cities—now imagine the environmental weight of that. Each tiny piece, from the laces to the branding patches, plays its part in turning sneakers into one of the fashion industry’s dirtiest secrets.

Whether you’re strapping on high-tops for style or lacing up runners for the gym, every step has a story—and now you know it’s one worth exploring further. Let’s dig deeper into what makes sneakers so environmentally complicated and why change is urgently needed.

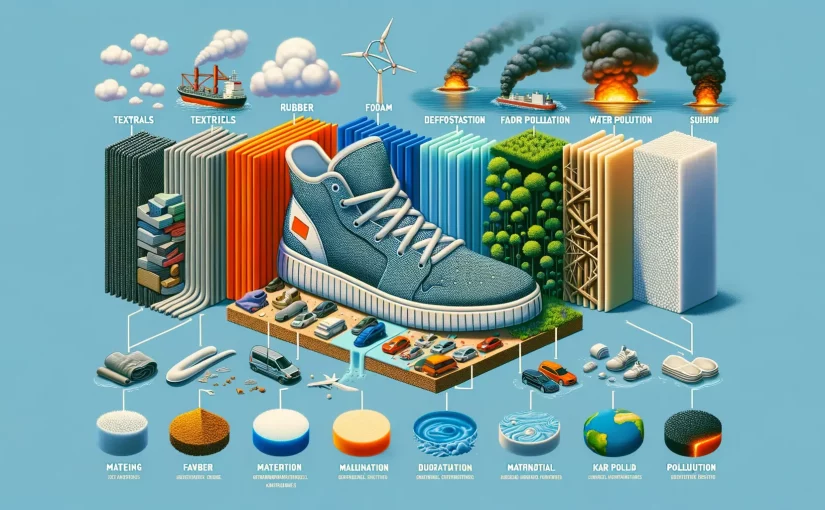

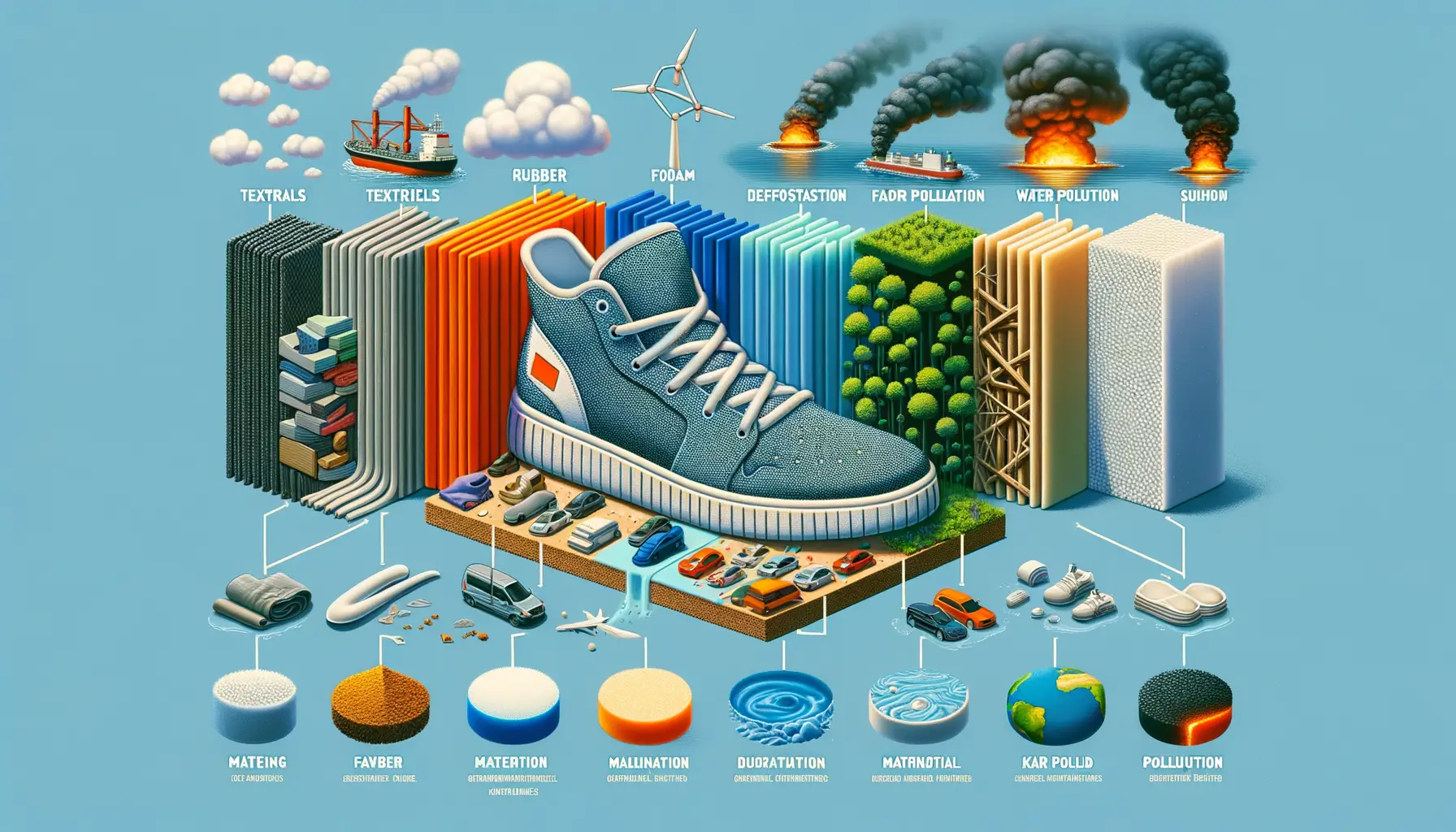

Key Materials Used in Sneaker Production and Their Environmental Costs

The Power Players: Leather, Polyester, and Rubber

Ever wondered what’s in your favorite sneakers? Let’s break it down. One of the heavy hitters is leather. Sure, it looks premium, feels durable, and ages gracefully, but its environmental weight? Enormous. Behind those buttery-soft uppers hides a dark side—deforestation for grazing land, methane-belching cows, and some seriously toxic tanning chemicals. Every leather sneaker carries a carbon shadow.

Then there’s polyester. This synthetic superstar brings stretch, strength, and sleek designs to your kicks. But here’s the reality check: polyester is made from petroleum. Manufacturing it releases heaps of CO2 and microplastics, which stick around in oceans longer than your gym routine.

And we can’t ignore rubber. While it keeps us bouncing comfortably, whether natural or synthetic, its production leaves a hefty ecological bill. Natural rubber taps into tropical forests, threatening biodiversity, while synthetic rubber is another petroleum-based culprit.

- Leather: High water usage, chemical-heavy processes.

- Polyester: Non-renewable, sheds microplastics.

- Rubber: Strains ecosystems, contributes to deforestation.

Each lace, sole, and stitch has an environmental footprint. What’s your pair made of?

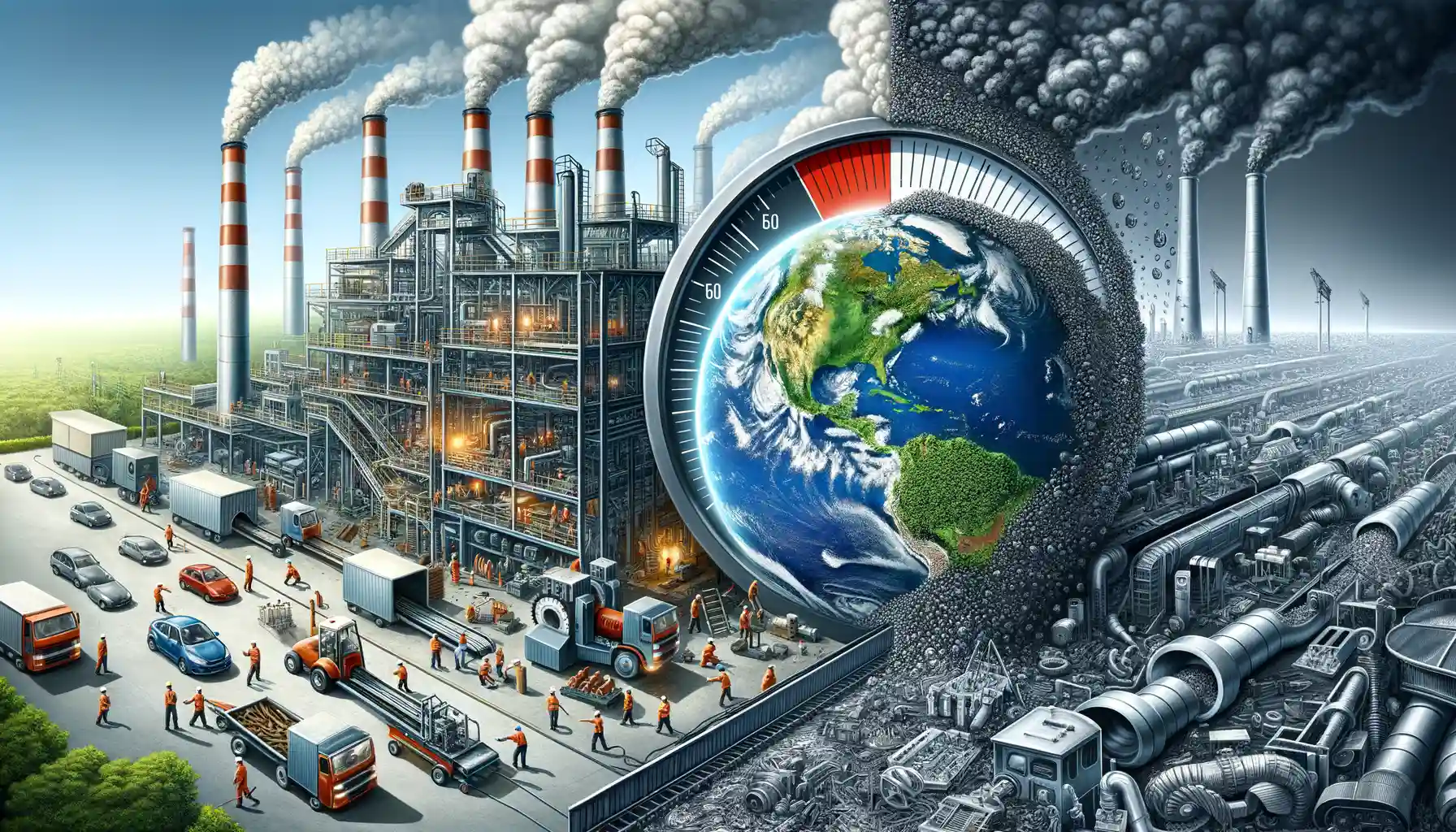

Manufacturing Processes and Carbon Footprint

The Hidden Energy Behind Each Pair

Ever wondered what your sneakers go through before they land on store shelves? The truth is, the manufacturing process is an energy-hungry beast. Imagine a symphony of machines cutting, stitching, molding, and assembling, each demanding electricity, water, and heat. Sneaker production often involves factories across different continents—rubber sourced in Asia, polyester coming from Europe, soles molded in South America. Each step requires fuel and energy, leaving behind a hefty carbon footprint.

Did you know that producing one pair of running shoes can emit up to 13kg of CO2? That’s like driving your car for 50 miles! The culprit? Processes like foam injection, which involve chemical reactions and high temperatures, or sewing machines running for hours. And let’s not forget the emissions from transporting materials before production even begins.

How Factories Stack Up

Not all factories are created equal. Some rely heavily on non-renewable sources like coal, while others are pivoting to greener alternatives. Here’s the breakdown:

- Traditional manufacturing hubs: High emissions due to outdated tech and fossil-fuel dependency.

- Sustainable factories: Solar panels, reduced water waste, and closed-loop systems.

Your sneakers’ story doesn’t just start at the store—it’s written in these factories.

Waste Management and Recycling Issues

The Sneaker Graveyard: A Growing Problem

Think of this: every time you toss an old pair of sneakers, where do they go? Unfortunately, most end up in sprawling landfills, where they’ll sit for decades—or even centuries. The catch? Many sneakers are made from a cocktail of synthetic materials like EVA foam, rubber, and polyester. These materials, while impressively durable, refuse to decompose anytime soon. What does that mean? Your favorite kicks might outlive you… by hundreds of years. Scary, right?

The Recycling Puzzle

Recycling sneakers isn’t as simple as tossing them into a blue bin. Unlike a glass jar or aluminum can, the average sneaker is a Frankenstein of materials glued, stitched, and molded together—making it notoriously hard to disassemble. Here’s the kicker: only a small percentage of sneakers are actually recycled properly.

- Complex designs: Mixed materials make separation almost impossible.

- Lack of infrastructure: Recycling centers aren’t equipped to handle footwear.

- Consumer habits: Many people don’t know their sneakers can (sometimes) be recycled—or where to do it.

The result? Mountains of sneakers choking our planet. If this visual doesn’t hit home, imagine your beloved running shoes turning into toxic microplastics that seep into waterways for generations. It’s an ugly truth worth addressing.

Solutions and Sustainable Practices in Sneaker Production

Revolutionizing Materials: A Step Away from Harm

What if your sneakers didn’t just look good but also did good? Brands are now shaking up the sneaker world by swapping out traditional materials for sustainable alternatives. Take, for instance, sneakers created from recycled ocean plastics. Imagine walking around knowing your shoes helped pull trash out of the sea!

Then, there’s the rise of plant-based materials like pineapple leather and natural rubber. These reduce dependency on petroleum-based materials, slashing emissions while giving you that same sleek, durable wear. The sneaker industry is finally realizing that sustainability doesn’t mean sacrificing style or performance—it means merging creativity with care for our planet.

- Biodegradable soles that decompose instead of lingering in landfills.

- Sneakers made from hemp or organic cotton—lightweight, breathable, and eco-friendly.

Cleaner Manufacturing: Small Steps, Big Impact

Here’s a thought: What if factories turned clean energy into cool kicks? Some companies are already doing that by using solar-powered production lines and investing in water-free dyeing techniques. Think of the gallons of water saved—a real game-changer in an industry notorious for waste.

Still, it doesn’t stop there. Modular design is a buzzword you’ll love. Picture sneakers you can repair instead of discarding, with interchangeable parts extending their life. It’s not just environmentally smart; it’s economically brilliant. When shoes last longer, we buy less—and the planet breathes a little easier.